Laboratory facilities

Room 0-8 located in the basement of the laboratory building, total floor area 278 m2 shared with Laboratory of Heating, Ventilation and Air-Conditioning and Laboratory of Thermal measurements. Laboratory of Refrigeration uses approximately 90 m2.

Room 2-122 at the first floor of laboratory building, total floor area 24 m2 shared with Laboratory of Heating, Ventilation and Air-Conditioning.

Room 2-121 at the first floor of laboratory building, total floor area 147 m2 shared with Laboratory of Heating, Ventilation and Air-Conditioning and Laboratory of Thermal measurements.

Laboratory activities

Teaching, scientific research and professional work in refrigeration, building energetics and thermal energy systems.

Scientific activities

Experimental research as a part of activities on scientific papers’ preparation, projects and dissertations in the field of refrigeration and heat pump technology and application.

Scientific projects

Finished

Applied research of refrigeration systems with new refrigerants; Project No. 069-0692972-2203 Croatian ministry of science, education and sport RH, 2007. – 2013., principal researcher prof. Branimir Pavković, D. Sc.

Numerical modelling and optimization of refrigeration equipment and systems; Project No. 0069-017 Croatian ministry of science and technology 2002. – 2006., principal researcher prof. Branimir Pavković, D. Sc.

Applied research of trigeneration systems with heat pumps operating with natural refrigerants, Research project University of Rijeka 2014. – 2018., principal researcher prof. Branimir Pavković, D. Sc.

Active

Optimization of heat pumps and refrigeration systems with low global warming potential refrigerants using numerical simulation, Research project University of Rijeka 2014. – 2018., principal researcher prof. Branimir Pavković, D. Sc.

https://spapp.uniri.hr/projekti/ProjectNO1801/Details/1141

Enhancement of the heat exchanger energy efficiency (HEXENER) – Croatian Science Foundation, principal researcher prof. Anica Trp D. Sc.

http://www.riteh.uniri.hr/en/znanost-old/existing-projects/hexener/

Teaching activities

Laboratory practice and presentation of the operation of refrigeration systems within the courses Refrigeration, Compressors, Laboratory practice, Process Plant Equipment and Marine HVACR Systems at the graduate university study of mechanical engineering.

Measurements within the preparation of doctoral dissertations and support in the implementation of postgraduate doctoral studies in the courses Selected Chapters on Refrigeration, Environmental Refrigeration and Numerical Modeling in Refrigeration.

Professional activities

- Preliminary energy studies and reports on energy audits within the preparation of energy certificates for buildings in the Republic of Croatia.

- Energy studies and feasibility studies of HVACR systems.

- Professional projects of HVACR systems.

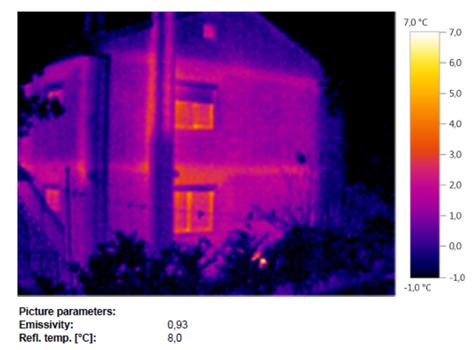

- Thermographic inspections of buildings and industrial facilities.

- Participation in the development of computer programs for determining the energy performance of buildings and their systems.

- Training of refrigeration system service technicians for operation and maintenance of refrigeration and air conditioning devices according to the project MP / CRO / 99/099 (2001-2013).

- Education and training of authorized service technicians to perform the activities of collection, leakage inspection, installation and maintenance or servicing of refrigeration and air conditioning units and heat pumps in accordance with the Regulation on certain fluorinated greenhouse gases (EC 517/2014) carried out in cooperation with the Croatian Association for refrigeration, air conditioning and heat pumps (HURKT)

- Education and training of those authorized for energy audits and certification of buildings with simple and complex systems.

- Education and training of authorized persons for energy audits and certification of large systems.

- Education and training of authorized service technicians to perform the activities of collection, leakage inspection, installation and maintenance or servicing of refrigeration and air conditioning devices and heat pumps that use CO2 or flammable refrigerants as a working substance

Laboratory equipment and systems

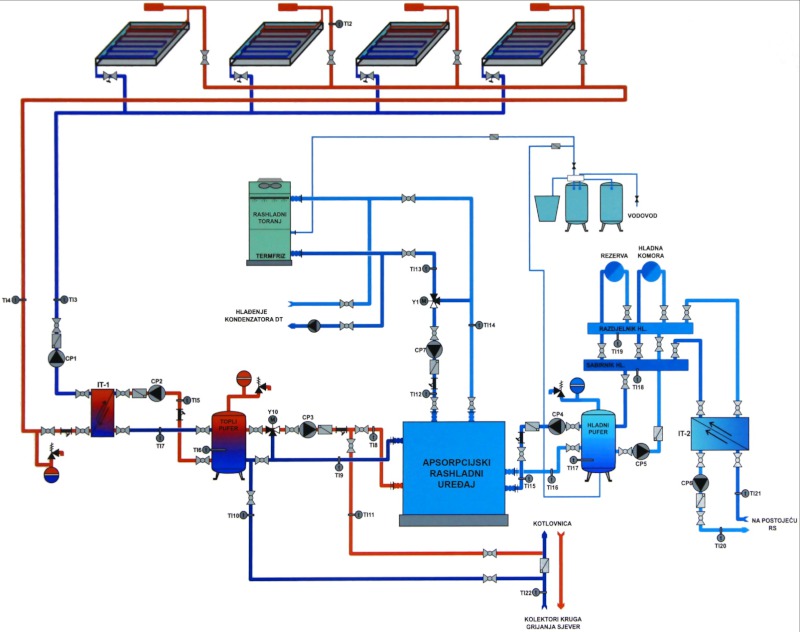

Solar cooling system

An experimental system of solar absorption cooling was installed in the laboratory of refrigeration financed by European project MED EMILIE and Faculty’s own funds.

The system enables cooling of the laboratory facility and it is used for educational and research purposes.

The cooling device works with a mixture of ammonia and water, its cooling capacity is 18.6 kW at at cooled water temperature of 6/12°C, heating water temperature from solar collectors 85/78°C and water temperature for cooling condenser and absorber 30/24°C. The required heat generated by solar collectors under these conditions is 30 kW, and the waste heat to be dissipated by the cooling tower is 49 kW.

The heat generated by absorber and condenser of the refrigeration unit is dissipated via an open cooling tower, a cooling effect of 131 kW at an outdoor air temperature of 31°C and a wet bulb temperature of 28°C.

The production of driving heat is through vacuum solar collectors with a total absorber area of 65 m2. The collectors are connected to each other in 4 groups of 5 collectors, located on the roof of the laboratory building, absorbers oriented to the south and inclined to the horizontal plane at an angle of 35°, which is carried out by rotating vacuum tubes around their axes lying in the horizontal plane.

In order to ensure the use of heat from solar collectors during the winter, to avoid possible increases in temperature and steam generation in the collectors and to ensure maximum utilization of solar energy, this project also envisages the use of solar energy for heating purposes. This is done by reheating the water from the laboratory building’s heating system via solar collectors.

Simplified scheme of solar cooling system

Collector field, cooling tower, dry cooler

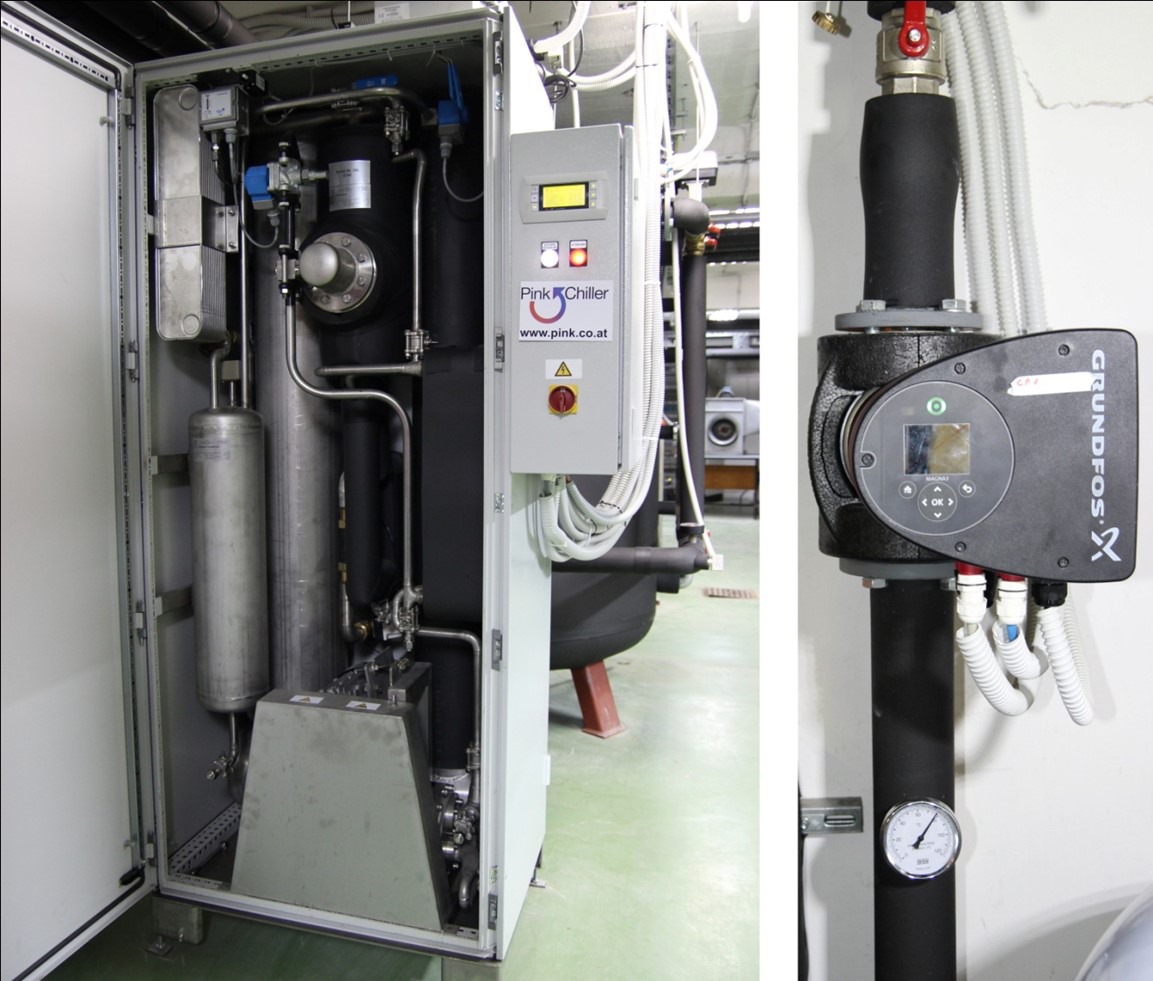

Absorption cooling device (left) and circulation pump at the outlet to the collectors (right)

Hot (left) and cold (right) heat storage

Machine room

Automatic control cabinet and collector field detail

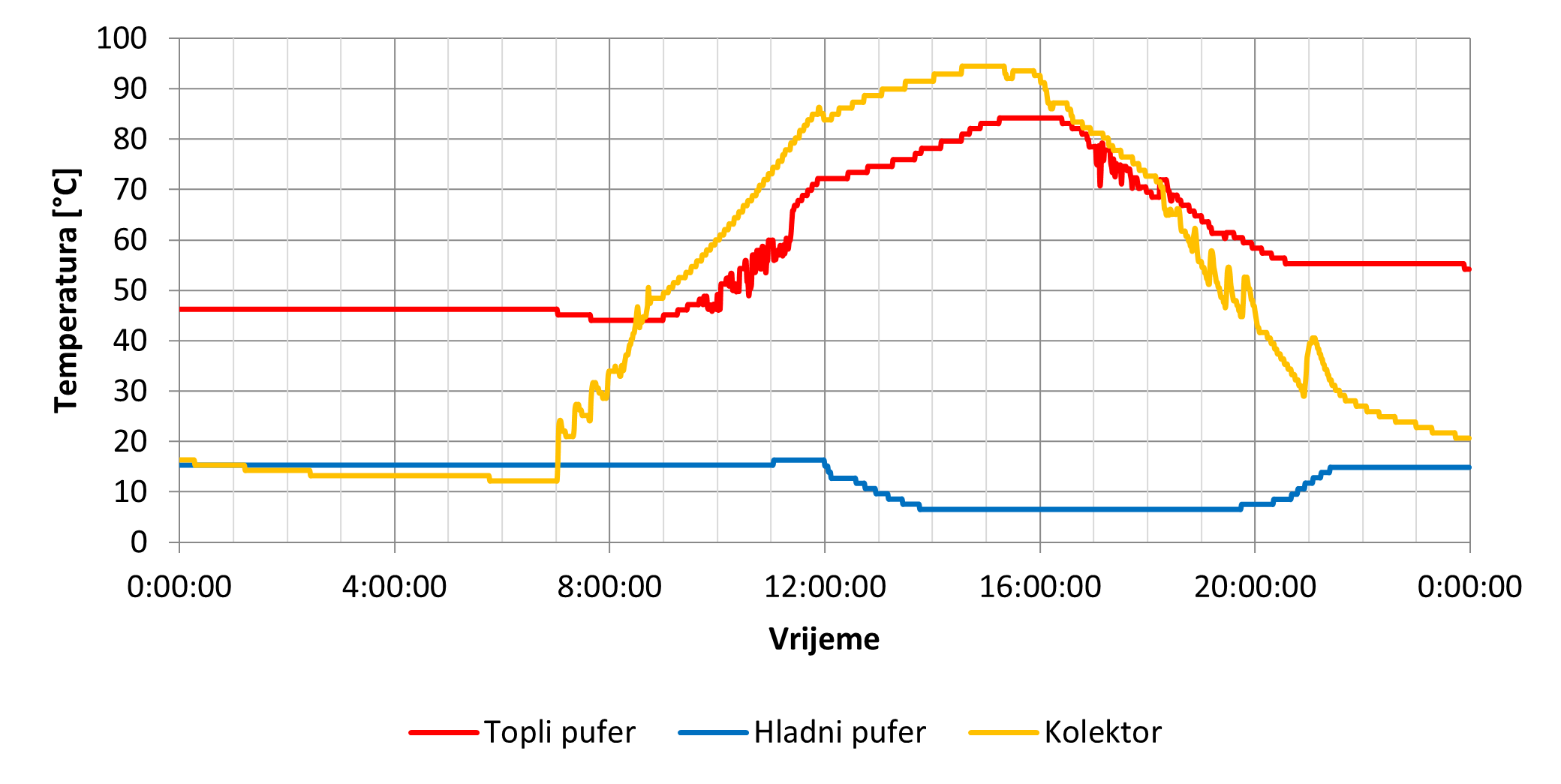

Measured values of temperatures in the hot and cold tank and at the outlet of the solar collector field, September 22, 2015

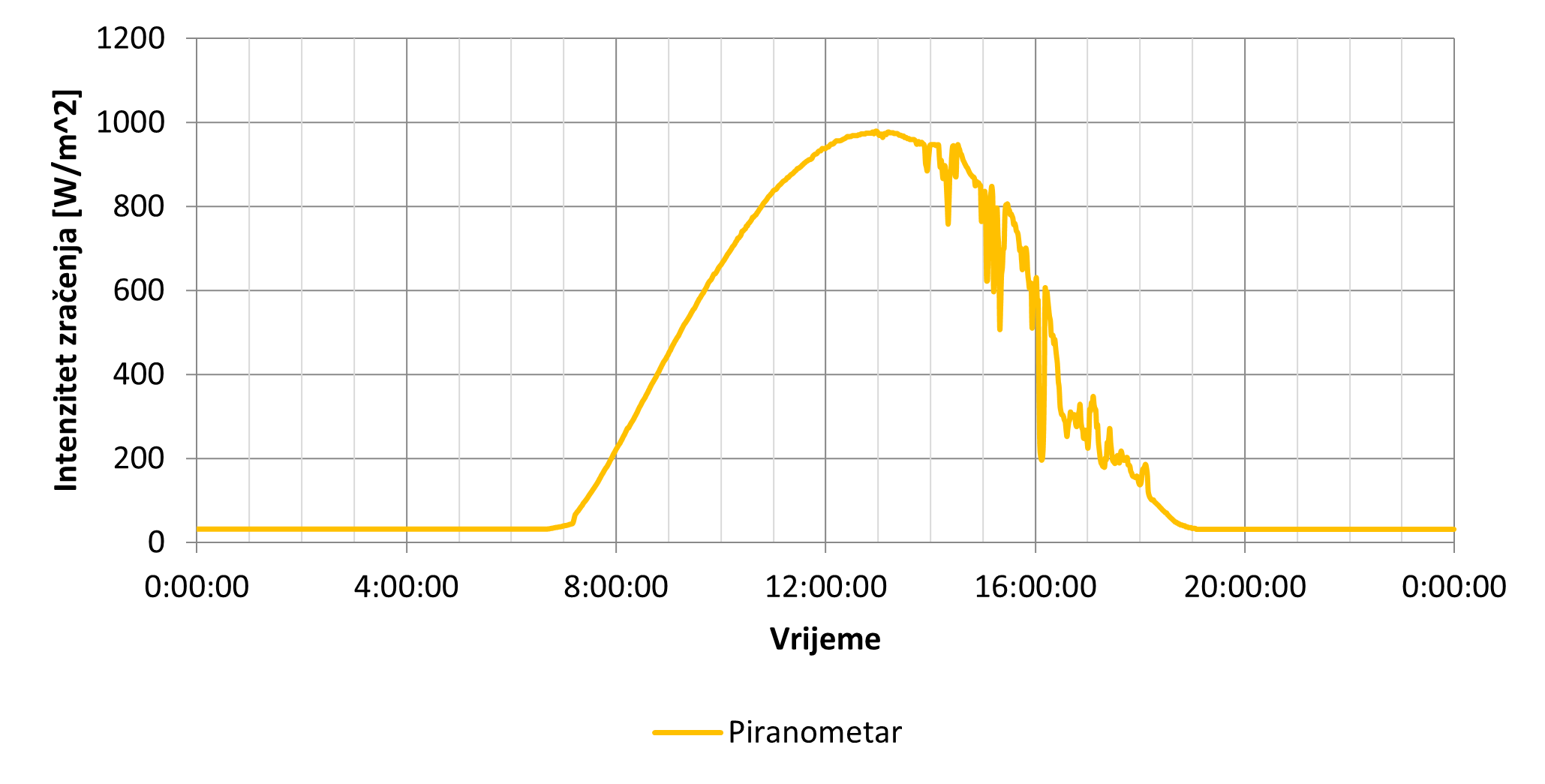

Measured values of solar radiation intensity, September 22, 2015

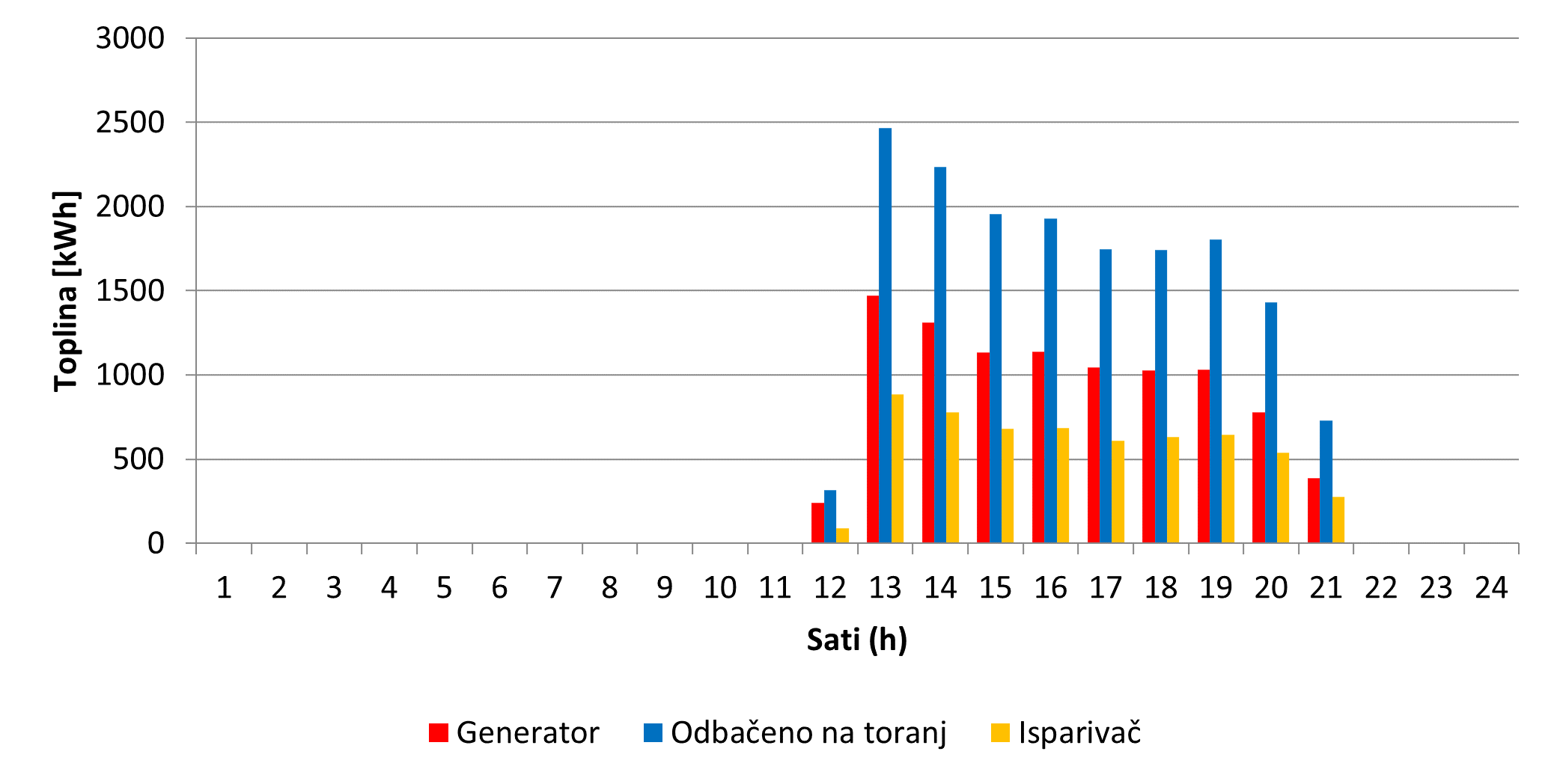

Heat balances, September 22, 2015

Cold storage with transcritical refrigeration unit working with CO2

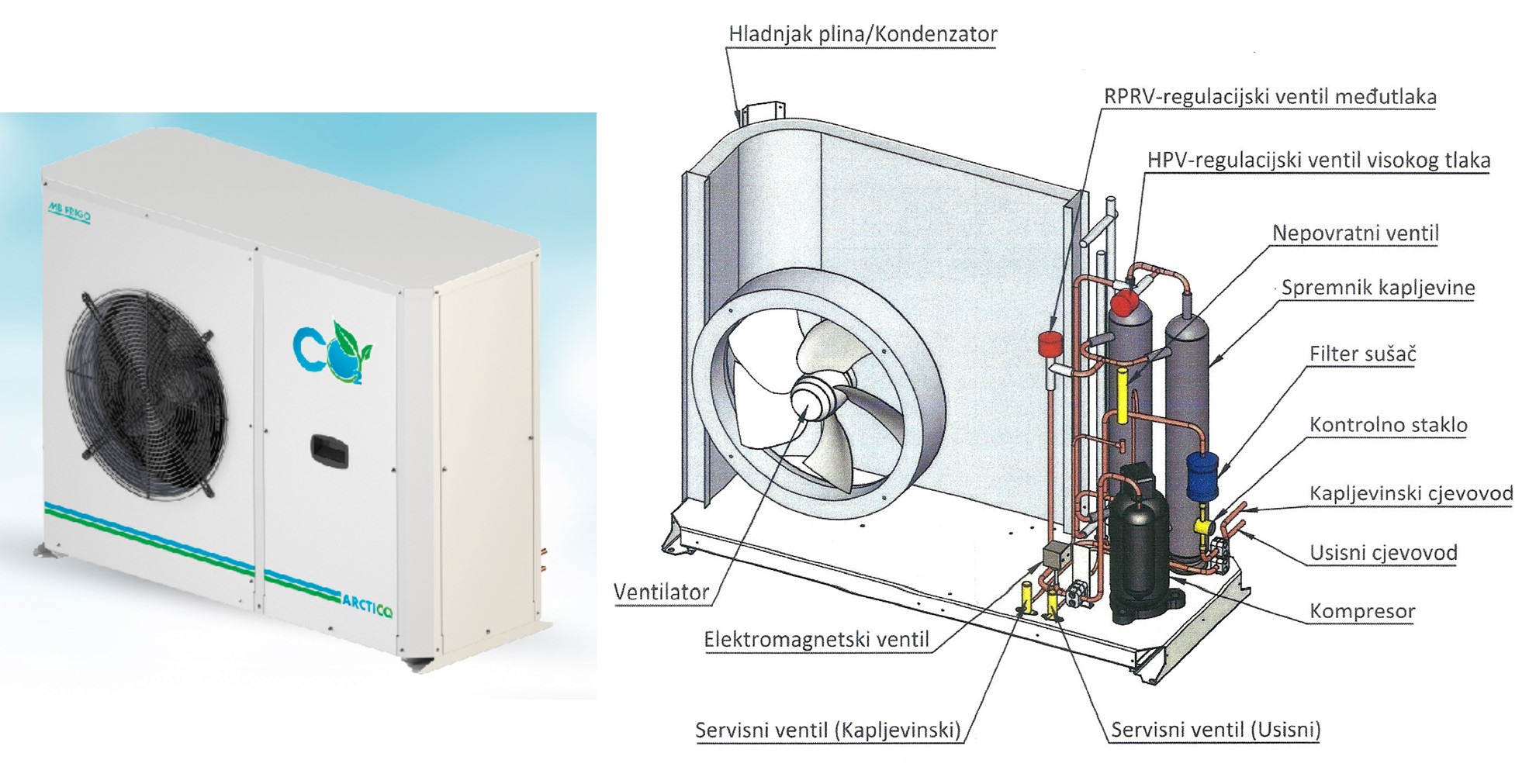

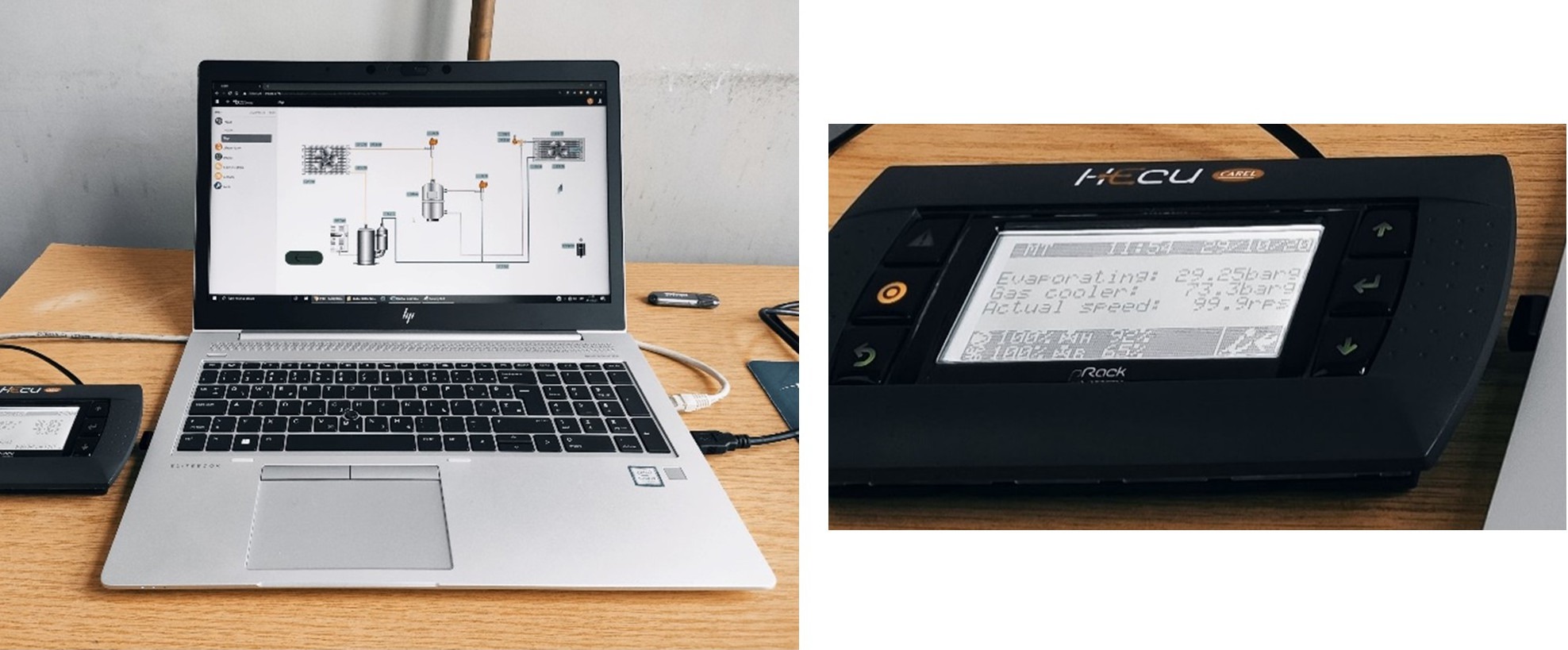

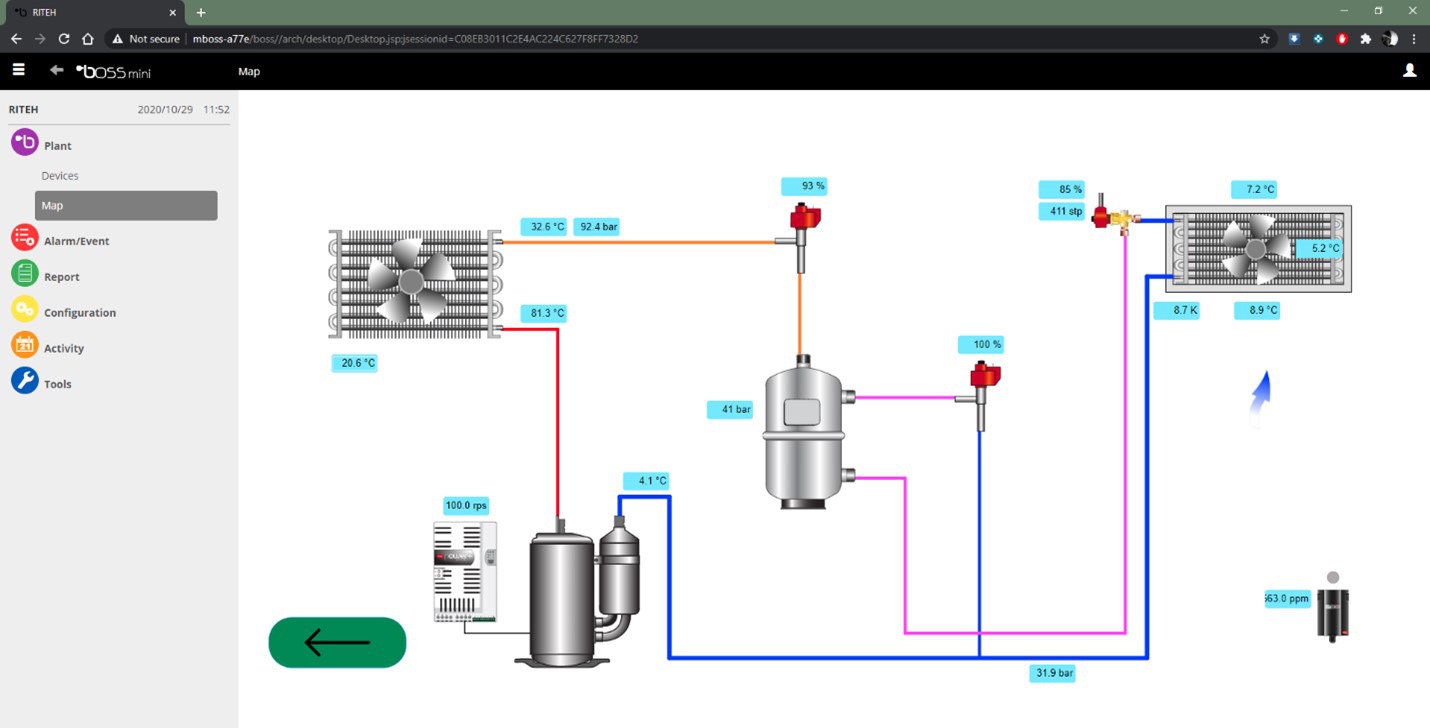

Refrigeration unit with CO2 refrigerant that works according to the transcritical cycle is one of the newer technical solutions for refrigeration devices in commercial applications. It was procured with the funds of the Faculty, while the corresponding cold store was donated by the manufacturer, the company MB Frigo d.o.o. from Zagreb. The device is equipped with an associated control and measuring system that allows monitoring of all operating parameters. As part of the classes in the course Refrigeration and Ship HVAC&R systems, exercises are held in which students are introduced to the operational principles. The device also provides performing the practical training for refrigeration service technicians. A dissertation is being prepared in which measurements intended for the evaluation of a computer model for simulating the operating parameters of the system in non-stationary operating conditions will be performed on this device.

Cold storage and evaporator

Condensing unit ARCTICO2 30 MB Frigo: compressor Toshiba DY30N1F-10FU (25 -100 rps), refrigerant R744, cooling capacity 0,7 – 2,8 kW (evaporation temperature -7°C, gas coole outlet temperature 35°C, superheating 10K). Gas cooler design pressure 120 bar. Evaporator design pressure 80 bar.

Monitoring and control (Carel HECU i BOSS)

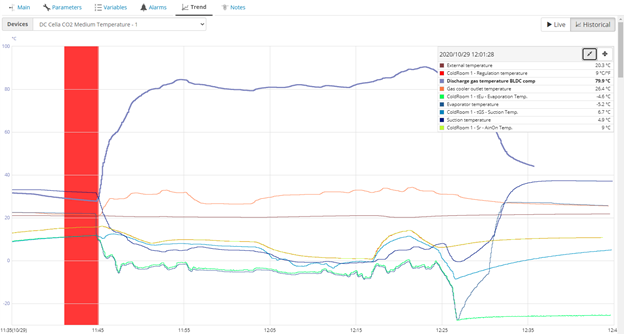

Pressure measurement log

Pressure measurement log

Front panel of the control unit

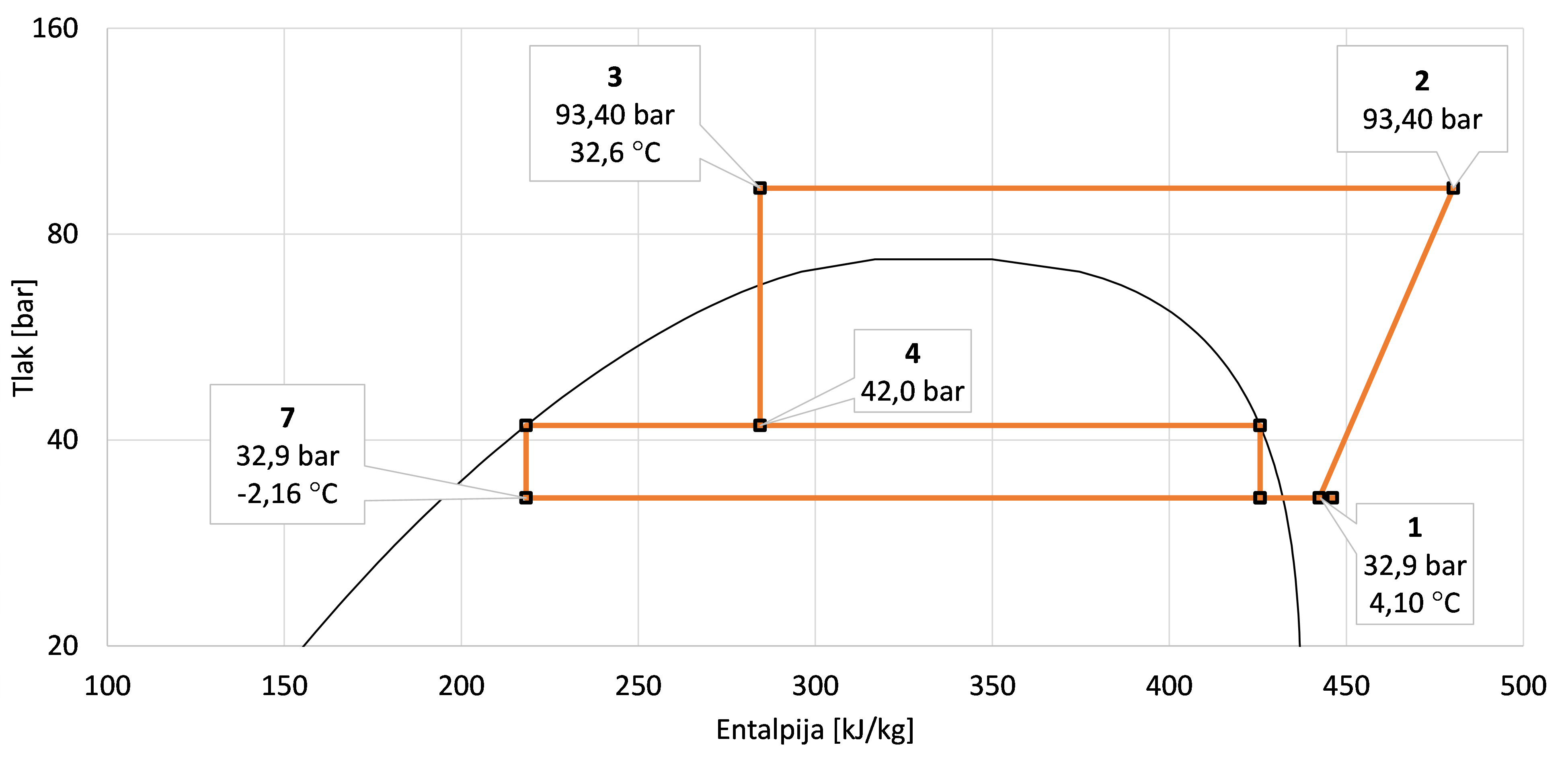

Operating points of the device (transcritical process)

In cooperation of the Faculty and the Croatian Association for Refrigeration Air Conditioning and Heat Pumps, the laboratory conducts practical training and development of refrigeration service technicians to work with devices that contain CO2 as a working substance.

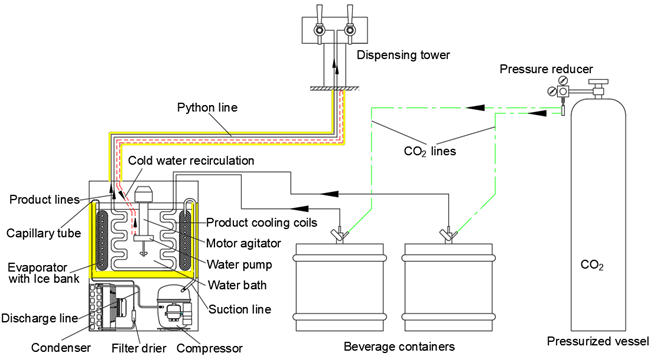

Draft beverage cooler with the latent heat storage

The device is donated by the company Oprema d.d. from Ludbreg. It is intended for cooling beverages when they are dispensed. The device is equipped for the implementation of measurements of operating parameters within the dissertation aimed at developing an integrated computer model of a refrigeration unit with latent accumulation that should serve to optimize the design of such devices in order to achieve increased energy efficiency.

Simplified scheme of draft beverage cooling system

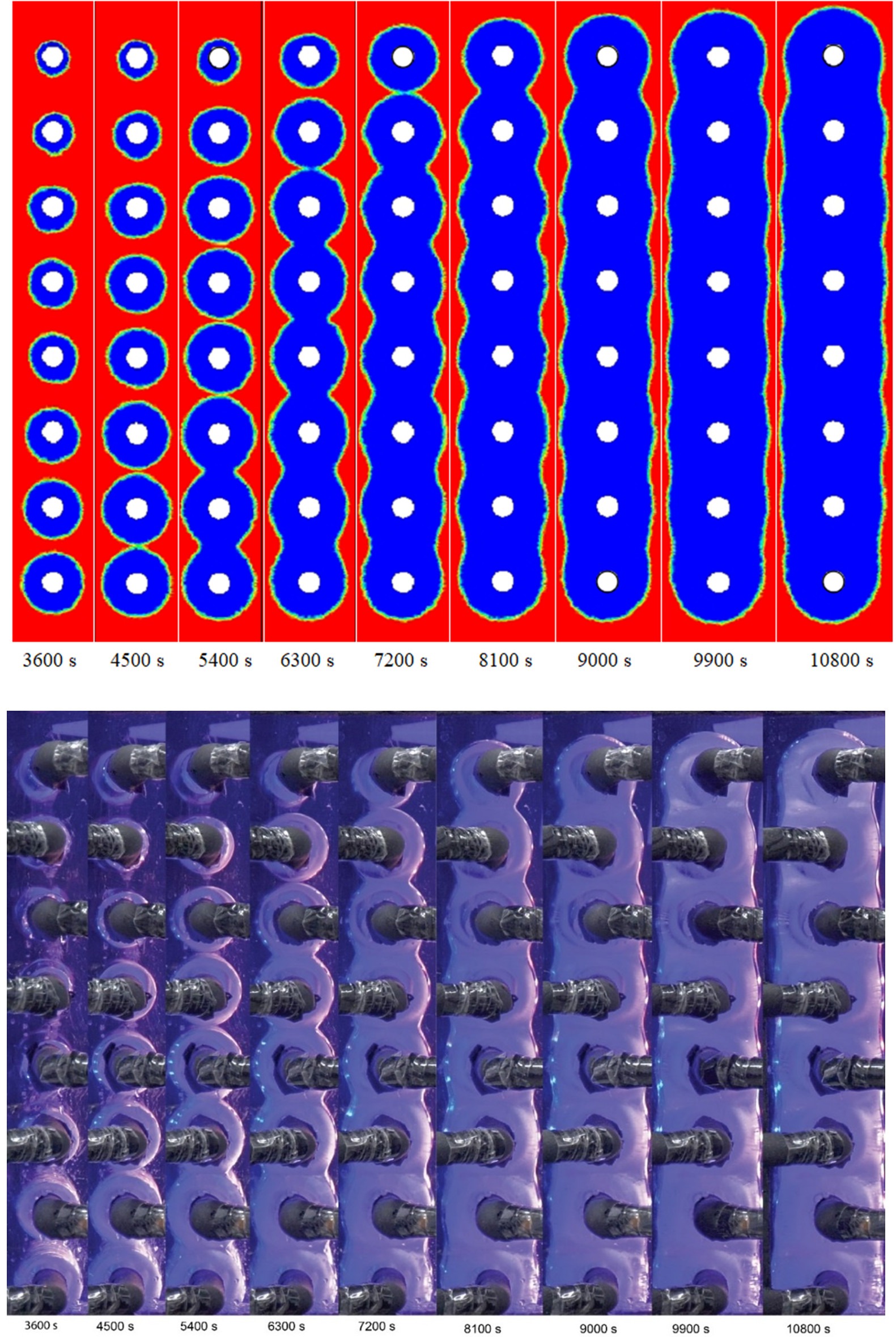

Computer simulations and experimental verification of ice formation on evaporator tubes

Vapor compression single stage refrigeration unit

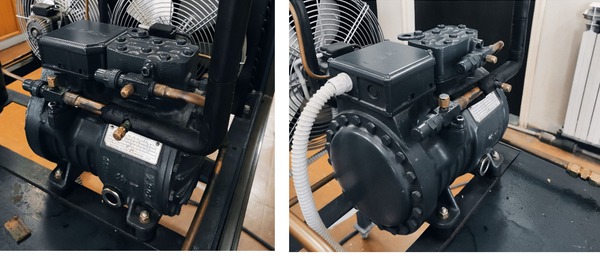

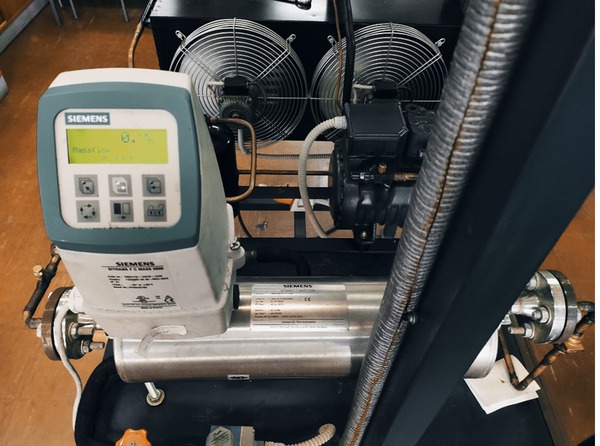

The device is intended to acquaint students with the principle of operation, the method of regulation and the interdependence of the operating parameters of refrigeration devices on the characteristics of individual components. It is also used for training of refrigeration service technicians engaged in working with refrigeration devices and their basic components, as well as for better acquaintance with refrigerants. It is equipped with inverter control of compressor supply and measurement of the flow of the refrigerant.

Heat pumps

All heat pumps in the refrigeration laboratory are connected in a single system that is integrated with the heating and cooling systems in the laboratory building. Heat pumps are equipped with inverter compressor control, devices for measuring refrigerant temperatures, pressures and mass flow, water temperature and mass flow, and compressor power. Measuring devices can be connected to acquisition systems that are an integral part of laboratory equipment and are intended for data collection and implementation of complex measurements. From the heat pumps shown in the pictures, the refrigerant R22 with which they were originally filled was removed and disposed and heat pumps were retrofitted and converted for use of new environmentally friendly refrigerants (HFC mixtures with low impact on global warming and propane).

Tools and equipment for working on refrigeration systems

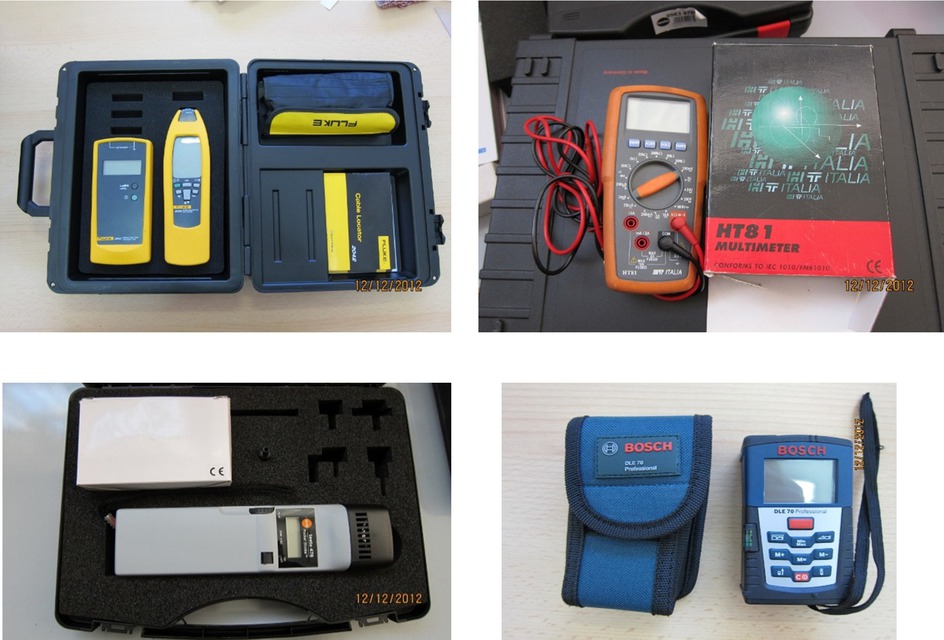

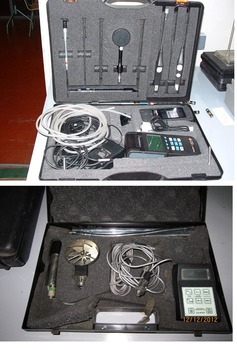

The laboratory has all the necessary equipment for refrigerant recovery, recycling and leakage detection, measurement of operating parameters as well as service equipment.

Small instruments

The laboratory uses several smaller instruments intended for measuring electrical quantities and operating parameters of devices and machines.

The laboratory is equipped with the necessary instruments to perform measurements on systems with water and air as heat transfer fluids.

Thermal imaging camera

It is used in the implementation of energy audits of buildings and in the analysis of the thermal state of technical systems in the laboratory.

Heat flow measuring device

It is used to measure the coefficients of heat transfer through the elements of building structures in the implementation of energy audits of buildings and in laboratory exercises for students of thermal engineering.

Cooperation with other laboratories of the Faculty

Laboratory for heating, ventilation and air-conditioning

Laboratory of thermal measurements

Financing

Faculty own resources

Funds of professional projects

Donations from companies and associations

Funds from scientific and EU projects, incentive projects of the University of Rijeka, etc.