Laboratory for Intelligent Machine Tools and Machining Systems

- Email address

- distokovic@riteh.uniri.hr

- Telephone

- +385 51 651467, int. 2467

- Location

- 3-08

Researchers:

Assist. Prof. Graciela Šterpin Valić, mag. ing. mech.

Assist. Hana Vukotić, univ. mag. ing. mech.

News from Laboratory:

On June 19, 2024, a presentation of the multi-axis CNC machining center development project (turn-mill) was held at 11:30 a.m. in the Counsel Hall of the Faculty of Engineering University of Rijeka.

Today's development of machine tools as mechatronic devices implies a wide spectrum of knowledge. Therefore, this presentation is the product of the presenter, Mr. Željko Pavlović's many years of interest and knowledge in areas related to production technologies and processes, construction, pneumatics and hydraulics, electronics, and machine control. His innovative spirit and energy are key to the realization of this idea.

Similar solutions exist on the global market, but this prototype solution surpasses the existing ones with a different approach. The interestingness of the presented concept lies in the combination of possibilities provided by the machine for industrial use and the specificity brought with it by solutions intended for schools, colleges, educational institutions in general, and hobbyists.

___________________________________________________________________________________________________________

On Thursday, February 1st and Friday, February 2nd, "Open Laboratory Days" were held at the Faculty of Engineering University of Rijeka, gathering a total of 640 students from 14 Croatian high schools. The work of the Laboratory for Intelligent Machine Tools and Machining Systems was presented and demonstrated to the students by doc.dr.sc. Graciela Šterpin Valić, assistant Hana Vukotić and senior laboratory technician Bernardo Badurina.

___________________________________________________________________________________________________________

In our Laboratory we use RoboDK for simulation and offline programming of industrial robots. Thanks to understanding the Laboratory's need for an appropriate software solution in robot programming, the Robo DK donated 30 educational licenses for one classroom at the Faculty of Engineering University of Rijeka.

Achievement of Laboratory, the article published in Journal Polymers (MDPI, ISSN 2073-4360) highly viewed and downloaded papers published in the 2019 year. More information on Twitter & LinkedIn

Laboratory purpose/research:

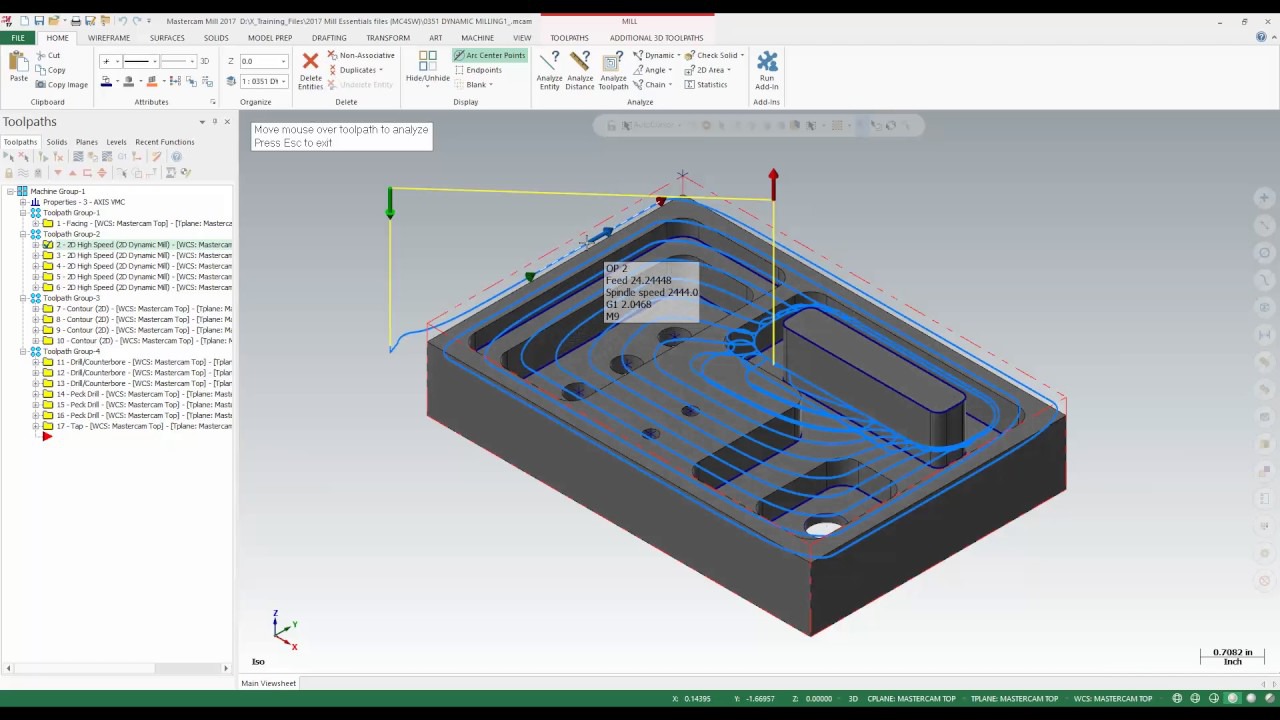

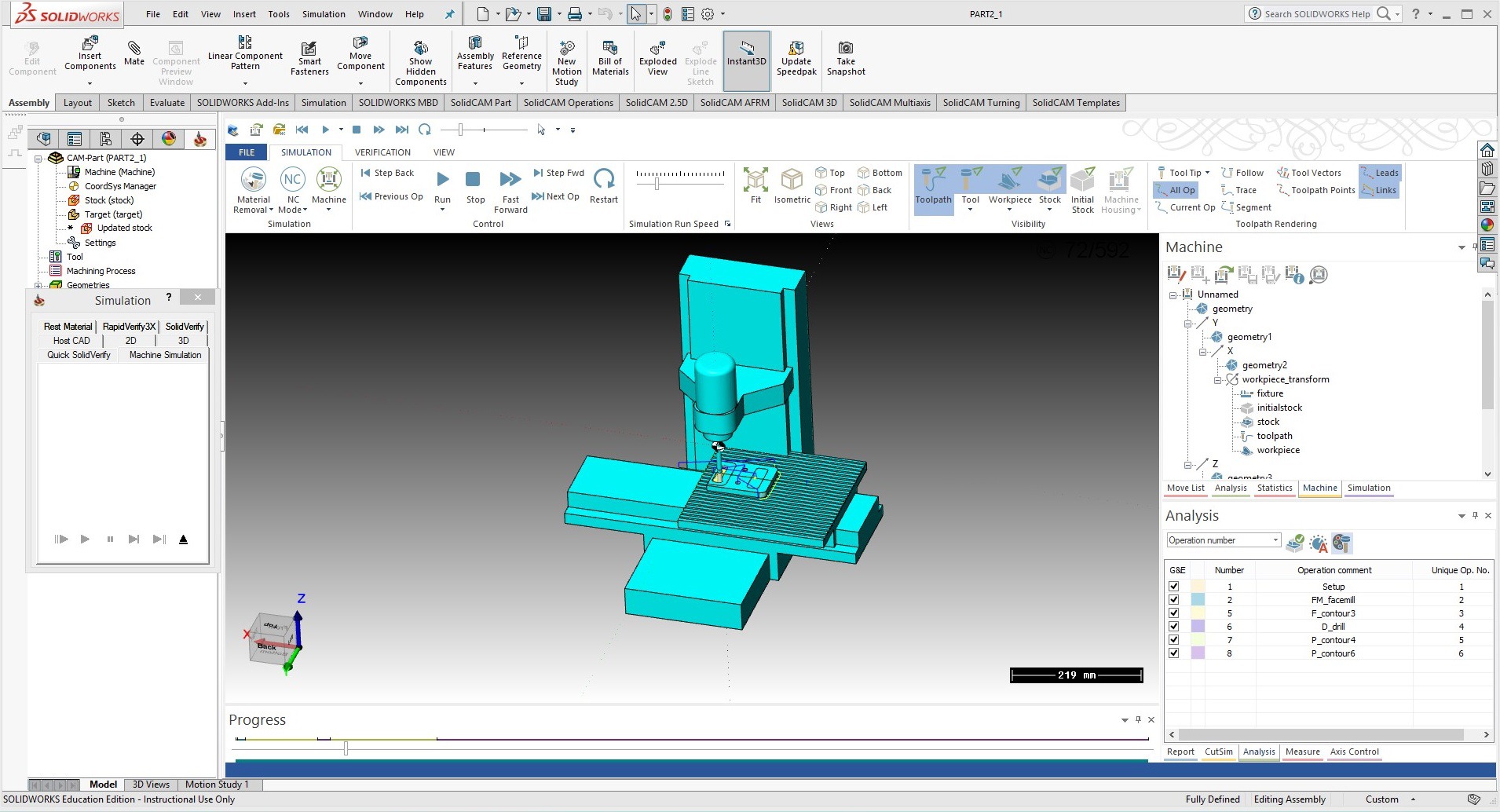

The laboratory fulfills its basic function through the teaching process at all levels of mechanical engineering studies. In addition to working with students on various CAD / CAM projects, the applications of CNC technology and reverse engineering activities of the Laboratory has also focused on cooperation with business subjects from the domain of mentioned technologies application. The laboratory members research in the field of modeling and simulation of machining and production processes using modern optimization methods to achieve optimal utilization of the resources.

Laboratory equipment:

-

CNC vertical machining center Bridgeport VMC560/22 (3-axis), Heidenhain TNC320 – technical specification

- Flexible manufacturing cell:

- 4-axis CNC milling machine - CNC STEP

- High-Z S-720 (x 720 mm y 420 mm z 110 mm) with automatic tool changer (tool holder magazine for max. 6 cutting tools SK15), water-cooled high-frequency spindle (600 W, 8000-27600 min-1) with additional equipment (cutting tools, ER11 collets, USB CNC remote control, adapters, controller software WinPC-NC & CAM software ConstruCAM, air compressor and notebook

- Pneumatic work holding - SMC

- Pneumatic cylinder MGP M50-250Z (max. stroke 250 mm, weight 8,55 kg, force 0,4¸2 kN)

- Robot arm – Commonplace Robotics

- MOVER 4–axis (payload: 500 g, reach 550mm) with two-finger gripper, 24V I/O extension to communicate with PLCs

- Belt conveyor - MiniTec

- 1500×250 mm and height 950 mm, electromotor (3,6 m/min) and frequency regulator Lenze, photocells

- PLC Siemens Simatic S7-1200 – TIA portal

- 4-axis CNC milling machine - CNC STEP

- 6-axis collaborative robot Yaskawa HC10DT and controller YRC1000 (video-example 1 - battery manipulation) (video-example 2 - robot writing) (video-example 3 - robot milling: RITEH, VW logo)

- Plasma cutting machine (own solution) table size 2000 mm × 1000 mm, Tomahawk 1025 (LC65) (material thickness up to 25mm), torch height controller Compact THC 150

- Cutting tools and basic measurement devices

- SLA 3D printer Form 2 - Formlabs

- 3D scanner - NextEngine

Software:

Teaching:

Undergraduate Vocational Study of Mechanical Engineering:

- Tools, Jigs and Fixtures

- Machine Tools

Undergraduate University Study of Mechanical Engineering:

- Production Machines, Tools, Jigs and Fixtures

Graduate University Study of Mechanical Engineering:

- Flexible and Intelligent Systems

- CNC/NC Machine Tools

- Industrial Robotics

Collaboration:

The laboratory has developed cooperation with business entities through various types of student, professional, and scientific projects, and in particular, emphasizes the following:

CAD/CAM software

CNC production

Cutting tools

Cutting tool holders

Machine tools

Other equipment

The Laboratory also has successful cooperation with domestic and abroad laboratories:

- Laboratory for CAD/CAM & Laboratory for Machine Tools, Department of Mechanical Engineering Technology, Faculty of Electrical Engineering, Mechanical Engineering and Naval Architecture, University of Split, Croatia

- Laboratory for Forming, Chair of Manufacturing Technologies and Systems, Faculty of Mechanical Engineering, University of Ljubljana, Slovenia

- Laboratory for Intelligent Manufacturing Systems, Chair of Production Engineering, Faculty of Mechanical Engineering, University of Maribor, Slovenia

- Laboratory for Non-Conventional Processing Method, Department of Production Engineering, Faculty of Technical Sciences, University of Novi Sad, Serbia